Conny Waters – AncientPages.com – The analysis of cauldrons dating back nearly two and a half millennia has enabled archaeologists to produce an almost exact replica, which gives valuable insight into the craftsmanship and techniques used by Iron Age metalworkers.

The replica cauldron. Credit: University of Leicester

More than ten years ago, archaeologists from the University of Leicester unearthed an impressive collection of Iron Age metal artifacts near Glenfield, Leicestershire, which significantly sheds light on the feasting rituals practiced by prehistoric communities.

The discovered metalwork includes a complete sword and dress items, such as pins and a brooch, but the majority of the collection consists of remnants from a set of eleven large cauldrons made from copper alloy and iron. This find is significant as it represents one of only two substantial collections of such objects known from Iron Age Europe.

The cauldrons played a significant role among the settlement’s inhabitants, who used them for feasting and ritual traditions.

The cauldrons consist of iron rims, hemispherical copper alloy bowls, and two iron ring handles attached to an iron band. They were found fragile and lifted in soil blocks for later analysis.

The delicate cauldron remains were treated carefully by conservators from MOLA (Museum of London Archaeology). After being interred for an extended period in the dense Leicestershire clay, the cauldrons had suffered corrosion and deformation.

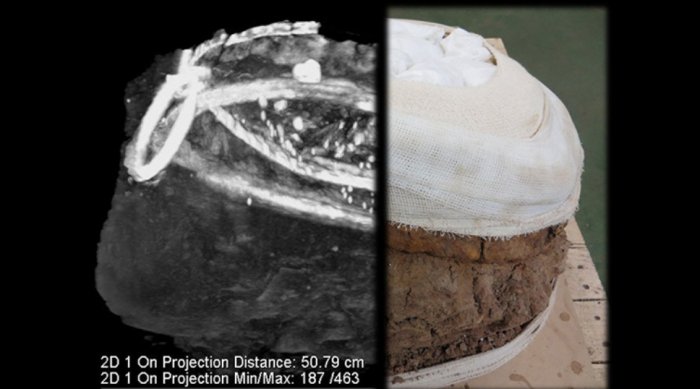

However, through a meticulous process involving CT-scanning, targeted X-ray scans, and careful cleaning and sampling, significant insights have been uncovered regarding their manufacture, usage, and condition before their disposal nearly 2,400 years ago.

Liz Barham, Senior Conservator at MOLA, explained that the careful conservation of the Glenfield Park cauldrons involved detailed recording, sampling, and scientific analysis. This process has revealed many new insights into how these cauldrons were made, repaired, and used during their functional lifespan.

Cauldron and CT scan montage. Credit: University of Leicester

Despite their crushed and corroded state, conservators have successfully identified numerous details that contribute significantly to research taht was conducted on previous cauldron discoveries.

An interesting aspect of the study is the discovery of intricate details about Iron Age metalworking skills, which reveal the use of sophisticated techniques to shape the thin copper sheeting of the bowl and to quench and weld the iron.

Multiple repair patches found on all of the cauldrons suggest that some mishaps occurred during their production, but also that once in use, they were carefully maintained and had long lives, indicating their importance to the community that used them.

“Cauldrons are substantial vessels associated with large gatherings and feasts, and the Glenfield examples are no exception, with capacities ranging between 15 and 57 litres they could have catered for several hundred people if all used at the same time,” explained John Thomas, director of the excavation and Deputy Director of ULAS.

“They must have been an important part of the feasting activities associated with this settlement but after a long period of use they were eventually buried in areas across the site for unknown reasons. This is the first time we have discovered such clear evidence for ancient feasting in Leicestershire and the results of the project will be important for understanding the social aspects of Iron Age communities in the Midlands and beyond.”

To understand how the cauldrons looked when they were in use, Hector Cole, a Master Arrowsmith and an archaeological ironworker, was commissioned to create a full-scale replica of a cauldron with the key features of the Glenfield collection.

He explained that forging the cauldrons was a steep learning curve, requiring me to think like the original makers. Their technical skills were exceptional, making them specialist cauldron makers of their time. Unlike today’s mechanical methods, they achieved precise hole drilling in bronze and iron by hand.

“They understood “creep” when assembling parts with rivets; doing it wrong distorted the shape irreparably. I was fortunate to know the correct technique for flawless assembly. I greatly respect Iron Age metalworkers and hope my work meets their standards of craftsmanship.”

Source

Paper

Written by Conny Waters – AncientPages.com Staff Writer